In engineering, CTRs serve as crucial elements in machinery and equipment, acting as load-bearing members or as part of anchoring systems. Their continuous threading enables efficient and precise adjustment, ensuring optimal performance in dynamic environments. Moreover, their ability to be cut to desired lengths makes them adaptable to different design specifications Moreover, their ability to be cut to desired lengths makes them adaptable to different design specifications

Advantages of Using Two Needle Embroidery Machines

A leather manual sewing machine is specifically designed to handle the unique challenges posed by sewing leather, a material that is thicker and tougher than standard fabrics. While modern electric sewing machines can often struggle with leather, the manual sewing machine is built with specific features that make it more suited for this purpose. It typically includes a walking foot mechanism, which aids in feeding layers of leather through the machine without slipping, ensuring even stitching. The machine also accommodates heavier threads and needles that are necessary for penetrating tough leather hides.

2. Sewing Technique

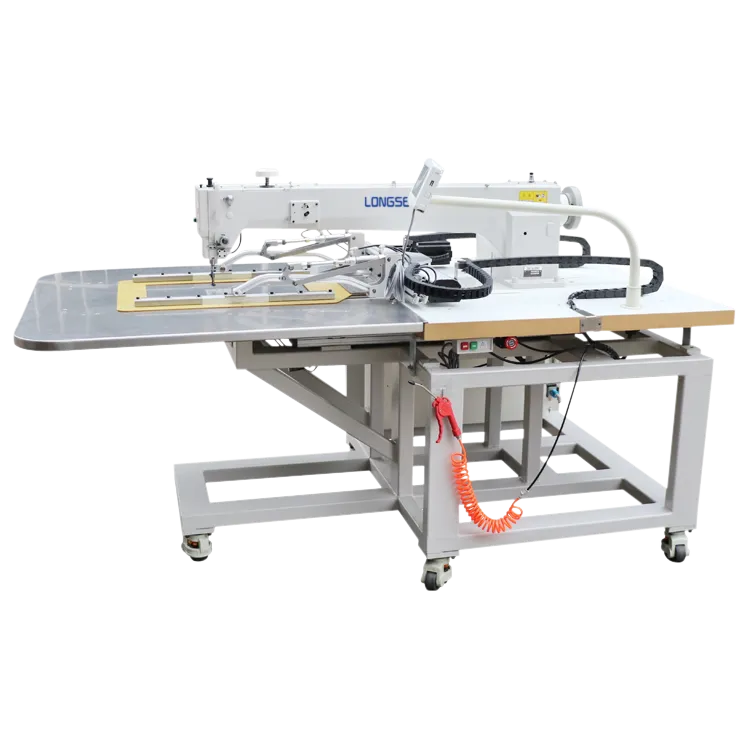

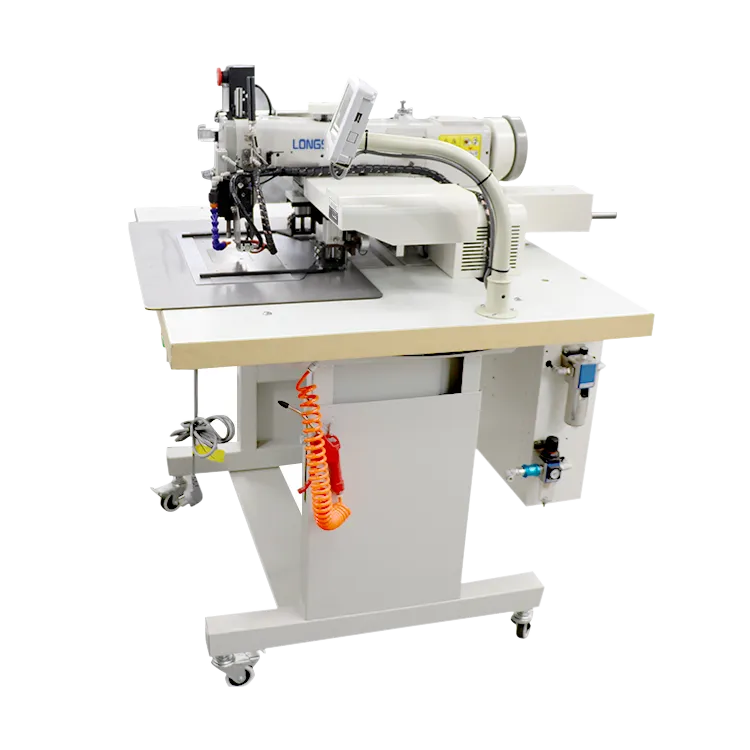

Moreover, the programmability of CNC machines offers designers the flexibility to modify designs easily. In the past, changing a sewing pattern required significant manual labor and reconfiguration, often resulting in wasted materials and time. With CNC technology, designers can rapidly adjust parameters and experiment with new styles without the need for extensive manual input. This adaptability leads to quicker turnaround times on new collections, enhancing a brand's agility in responding to fashion trends.

cnc programmable sewing machine

4. Cost-Effective Although the initial investment in an industrial overlocker may be higher than a standard sewing machine, the long-term benefits, including reduced labor costs and improved fabric usage, can lead to significant savings.

industrial overlocker for sale

Additionally, the trend towards automation in various industries suggests that CNC machine sewing may become a standard practice in textile manufacturing. As costs decrease and technology becomes more accessible, smaller businesses will also benefit from CNC capabilities.

1. Sewing Machines Typically used in industries such as textiles and food packaging, bag sewing machines utilize industrial threads to stitch bag tops securely. This method is particularly effective for multi-wall paper bags, as well as woven polypropylene bags. The durability of the sewn closure makes it a preferred choice for heavy or bulk products.

bag closing machinery

Another great option is the Brother GX37, which offers a user-friendly self-threading mechanism along with a plethora of built-in stitches. This versatility allows crafters to experiment with different sewing techniques and styles without feeling overwhelmed. The Brother GX37 not only makes threading easy but also provides comprehensive options for more advanced sewing tasks, making it a perfect choice for both beginners and experienced sewists.

easiest self threading sewing machine

Chain stitch sewing machines have become a fundamental tool in the textile and garment industry, renowned for their unique stitching technique and versatility. This specialized machinery creates a series of interconnected loops, forming a chain-like pattern that is not only strong but also offers significant elasticity. Introduced in the 19th century, chain stitch machines have evolved over the years, integrating modern technology while retaining their original charm and functionality.

2. Machine Specifications The complexity of the machine significantly affects its price. For instance, machines with automatic controls, multiple sealing options, and those that can handle different bag types typically come at a higher cost. Features such as adjustable speed settings, durability for heavy-duty use, and ease of maintenance also contribute to the overall price.

Sewing has long been regarded as a valuable skill, allowing individuals to create beautiful garments, home décor, and more. However, the complexity of threading a sewing machine often deters beginners and seasoned crafters alike from diving into this rewarding hobby. Fortunately, the advent of self-threading sewing machines has simplified this process, making it easier than ever for anyone to unleash their creativity.

Despite the technological advancements, many craftsmen still value the human touch in leatherwork. The integration of machines does not replace the artisan’s skills; rather, it complements them. Many artisans use machines for the bulk of the stitching, then finish products with hand-stitched details, adding a unique touch that reflects their craftsmanship and storytelling.

Moreover, their ability to be cut to desired lengths makes them adaptable to different design specifications Moreover, their ability to be cut to desired lengths makes them adaptable to different design specifications

Moreover, their ability to be cut to desired lengths makes them adaptable to different design specifications Moreover, their ability to be cut to desired lengths makes them adaptable to different design specifications